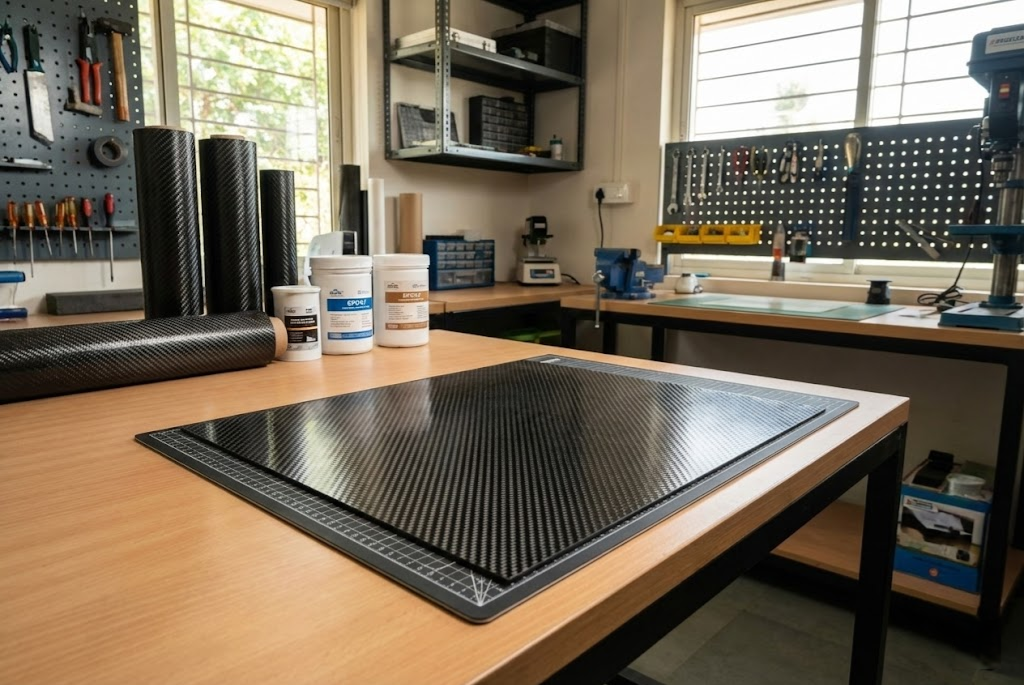

Composite Part Manufacturing & Fabrication

We provide custom composite part manufacturing for a wide range of applications, producing lightweight and durable components using carbon fiber, fiberglass, and natural fiber composites. From early-stage prototypes to production-ready parts, our fabrication process is focused on quality, precision, and performance.

Composite Part Manufacturing Overview

We provide custom composite fabrication for prototypes and production-ready parts, delivering lightweight, durable components built to your design and performance requirements. Our workflow supports one-off builds, small batches, and iterative development for a wide range of applications.

Using materials such as carbon fiber, fiberglass (CSM and woven roving), and natural fibers like jute and flax, we tailor each layup for strength, stiffness, and weight targets. From moulded components to finished parts, we focus on consistent quality, clean finishes, and reliable results.

Order & Requirements

We confirm your part requirements, quantities, material preferences, and delivery timeline to start production smoothly.

Raw Material Procurement

We source the required composite materials and consumables (carbon fiber, fiberglass, resins, cores) based on your specifications.

Mould & Part Production

We produce the mould (if needed) and manufacture your composite parts using controlled layup and curing for consistent results.

Post-Processing, QC & Delivery

Parts are trimmed, finished, and quality-checked before secure packaging and on-time delivery.

Production-Ready Quality

Manufacture reliable composite parts with consistent quality, suitable for research validation, functional testing, and real-world use.

Fast Prototyping & Iteration

Quick turnaround times enable rapid prototyping and design iteration for corporate R&D teams and individual innovators.

Wide Material Capability

Access carbon fiber, fiberglass (CSM and woven roving), and natural fiber composites to match performance, weight, and cost targets.

Flexible Order Volumes

Support for one-off parts, small batches, and limited production runs—ideal for research, startups, and custom projects.